How to repair a fiber optic patch cord?

2025-09-08

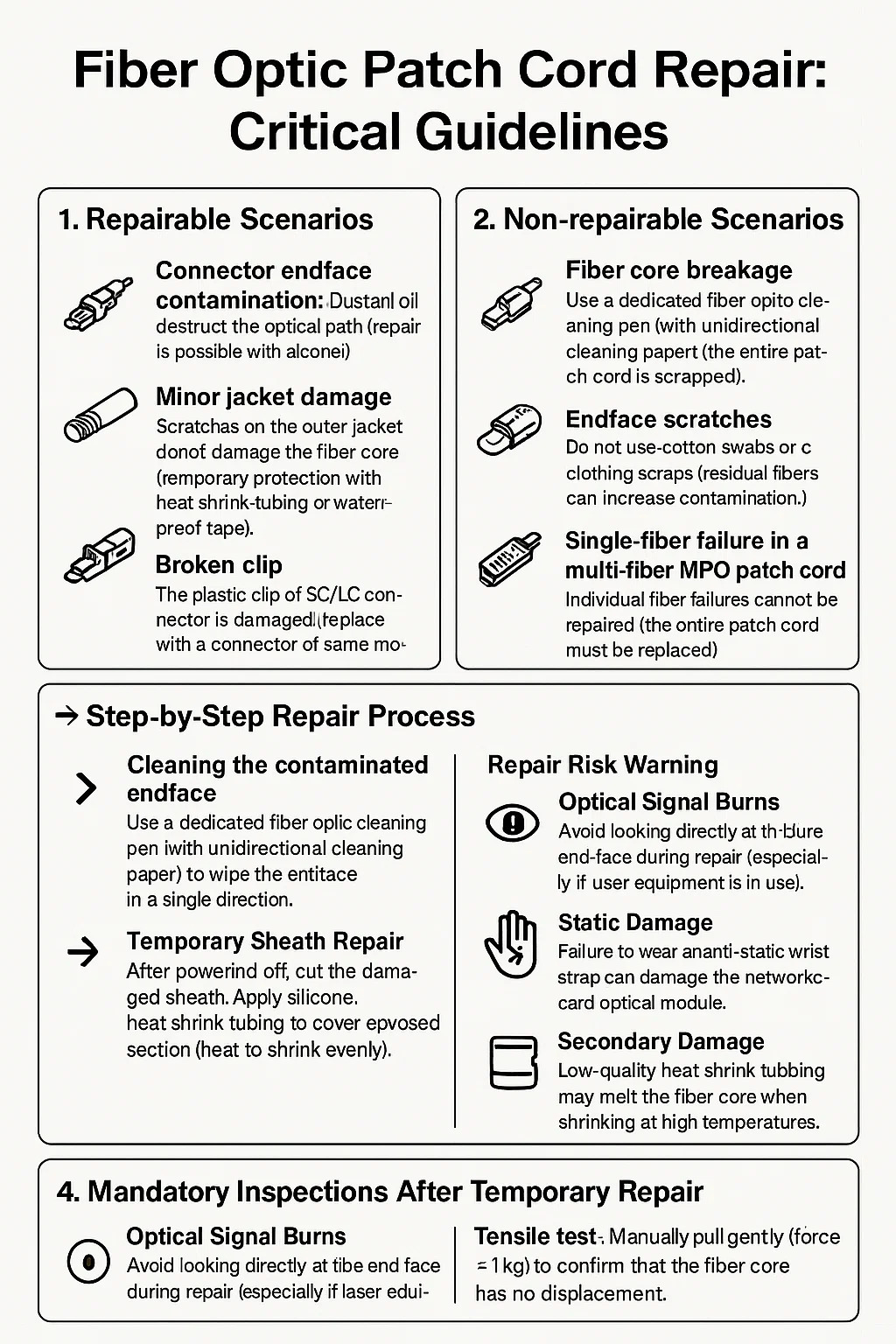

Fiber Optic Patch Cord Repair: Critical Guidelines

1. Repairable Scenarios

Connector endface contamination: Dust and oil obstruct the optical path (repair is possible with alcohol and non-woven fabric).

Minor jacket damage: Scratches on the outer jacket do not damage the fiber core (temporary protection with heat shrink tubing or waterproof tape).

Broken clip: The plastic clip of the SC/LC connector is damaged (replace with a connector of the same model).

2. Non-repairable Scenarios

Fiber core breakage: Excessive bending or squeezing causes the glass fiber to break (the entire patch cord is scrapped).

Endface scratches: Scratches on the ceramic ferrule greater than 0.2µm (permanent signal degradation).

Single-fiber failure in a multi-fiber MPO patch cord: Individual fiber failures cannot be repaired (the entire patch cord must be replaced).

3. Step-by-Step Repair Process

► Cleaning the contaminated endface

Use a dedicated fiber optic cleaning pen (with unidirectional cleaning paper) to wipe the endface in a single direction.

Do not use cotton swabs or clothing scraps (residual fibers can increase contamination).

Verify continuity with a red laser pointer.

► Temporary Sheath Repair

After powering off, cut the damaged sheath.

Apply silicone heat shrink tubing to cover the exposed section (heat to shrink evenly).

Armored patch cables should be sealed with metallic tape and epoxy resin.

► Connector Replacement

Cut off the pigtail section from the original connector (leave at least 30cm of excess).

Fiber Stripping: Use Miller pliers to remove the coating and clean the bare fiber with alcohol.

Insert the new LC/SC connector and cure the fiber core with epoxy resin.

Polish the end face with a grinder (mandatory step; manual polishing is unreliable).

4. Repair Risk Warning

Optical Signal Burns: Avoid looking directly at the fiber end face during repair (especially if laser equipment is in use).

Static Damage: Failure to wear an anti-static wrist strap can damage the network card optical module.

Secondary Damage: Low-quality heat shrink tubing may melt the fiber core when shrinking at high temperatures.

5. Mandatory Inspections After Temporary Repair

Optical Power Test: The attenuation value must be <0.5dB higher than the original manufacturer's standard. Tensile test: Manually pull gently (force ≤ 1kg) to confirm that the fiber core has no displacement.

Bend test: Wrap around a 4cm diameter cylinder three times, optical power fluctuation <0.2dB.

cooperate with PUXIN?

Contact us to find out how our products can transform your business and

take it to the next level.