How to reuse keystone jacks and field termination plugs?

2025-11-17

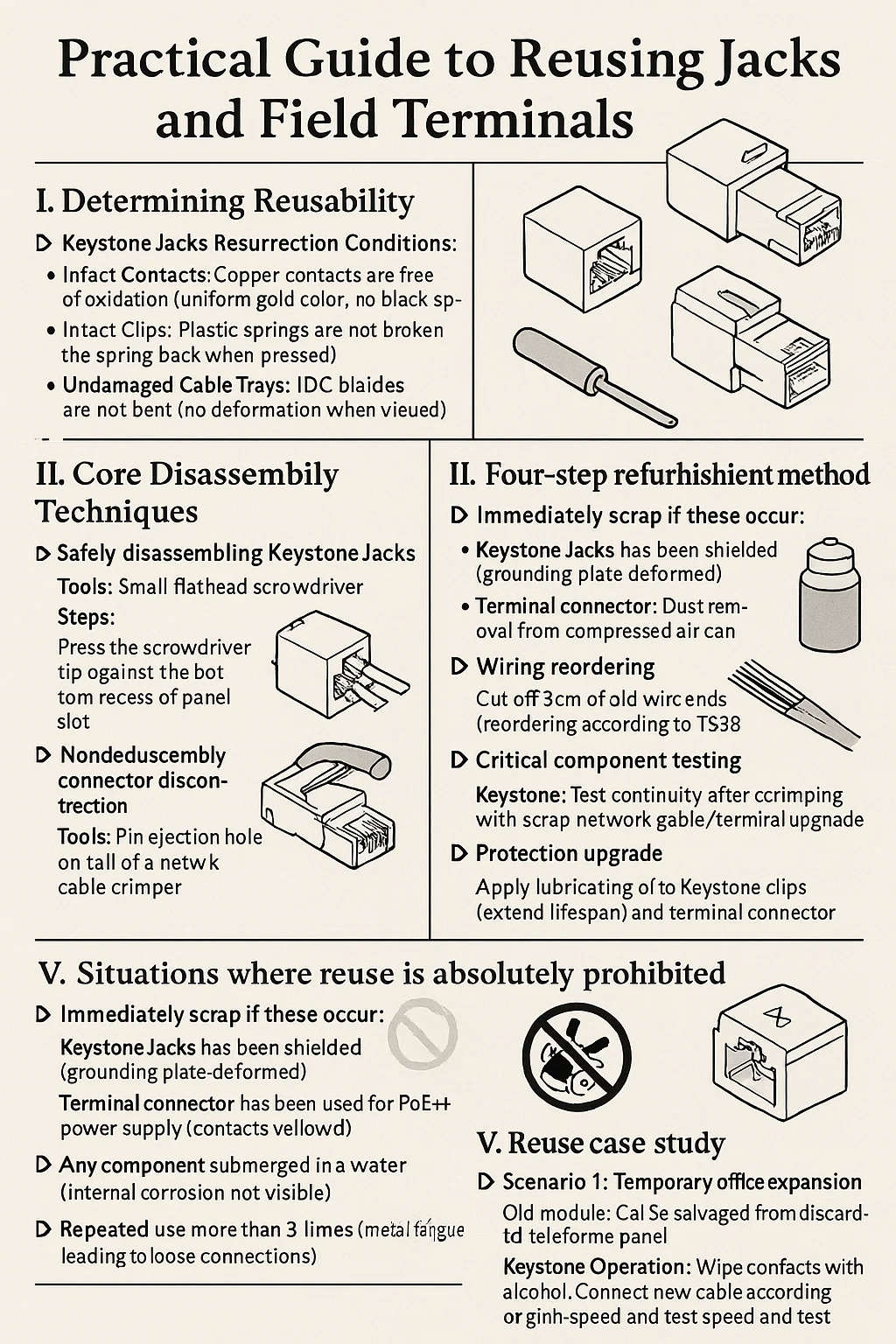

Practical Guide to Reusing Keystone Jacks and Field Termination Plugs

Content

I. Determining Reusability

▸Keystone Jacks Resurrection Conditions:

Intact Contacts: Copper contacts are free of oxidation (uniform gold color, no black spots)

Intact Clips: Plastic springs are not broken (they spring back when pressed)

Undamaged Cable Trays: IDC blades are not bent (no deformation when viewed against the light)

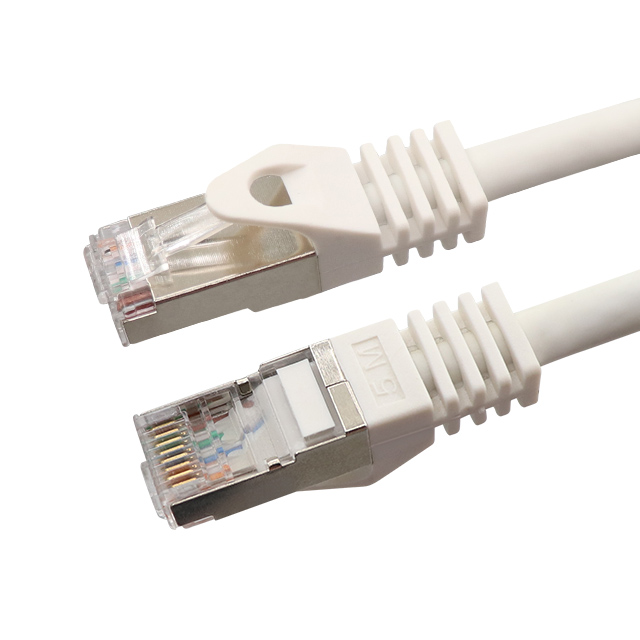

▸Terminal Applicability:

No Cracks in the Plug Shell: Especially at the base of the latch

Insulation Plate in Place: The transparent separator inside the RJ45 connector is not detached

No Worn Plating: Contact points still reflect light

II. Core Disassembly Techniques

▸Safely Disassembling Keystone Jacks:

Tools: Small flathead screwdriver

Steps:

Press the screwdriver tip against the bottom recess of the panel slot.

Gently pry while simultaneously pushing the module out with your thumb.

Caution: Do not pull the cable forcefully!

▸Non-destructive connector disconnection:

Tools: Pin ejection hole on the tail of a network cable crimper

Steps: Place the pin ejection hole on the front of the RJ45 connector with the crimper.

Rotate while pulling back (preserving the original wiring sequence)

III. Four-step refurbishment method

▸Deep cleaning:

Keystone contacts → Gently wipe with anhydrous alcohol wipes.

Contact interior → Dust removal from compressed air canister

▸ Wiring reordering:

Cut off 3cm of old wire ends (remove creased sections)

Reorder according to T568B (orange-white/orange/green-white/blue/blue-white/green/brown-white/brown)

▸ Critical component testing:

Keystone: Test continuity after crimping with scrap network cable

Terminal connector: Temporarily crimp to a short wire for testing

▸ Protection upgrade:

Apply lubricating oil to Keystone clips (extend lifespan)

Apply insulating silicone grease to terminal connector plug/plug ports

IV. Situations where reuse is absolutely prohibited

▸ Immediately scrap if these occur:

Keystone Jacks has been shielded (grounding plate deformed)

Terminal connector has been used for PoE++ power supply (contacts yellowed and carbonized)

Any component has been submerged in water (internal corrosion not visible)

Repeated use more than 3 times (metal fatigue leading to loose connections)

V. Reuse case study

▸ Scenario 1: Temporary office expansion

Old module: Cat5e salvaged from a discarded telephone panel Keystone Operation: Wipe contacts with alcohol. Connect new cable according to the original color code. Connect to the switch and test speed; if it meets the requirements, it's ready to use.

▸Scenario 2: Surveillance Camera Repair

Old connector: Cut off the waterproof connector from the faulty camera.

Operation: Remove pins, keeping the connector shell. Insert new cable into the original waterproof plug. Crim the connector and then put it back into the shell.

cooperate with PUXIN?

Contact us to find out how our products can transform your business and

take it to the next level.