Can fiber optic patch cord be used for video surveillance?

2025-08-05

Yes, fiber optic patch cords can be applied to video surveillance systems, but they need to be adapted to specific scenarios. The core points are as follows:

1. Applicable scenarios and advantages

Long distance transmission: Replace copper cables to solve the problem of signal attenuation over 100 meters (such as perimeter cameras in the park and cross building monitoring).

Anti interference requirements: In places with strong electromagnetic interference such as high-voltage power stations and factory welding areas, fiber optic patch cords ensure that the image is free of snowflakes/jitter.

Essential for high-definition video: 4K/8K cameras require * *>100Mbps bandwidth * *, and multi-mode OM3 patch cords can stably carry gigabit data streams.

2. Deployment key limitations

Optoelectronic conversion dependence:

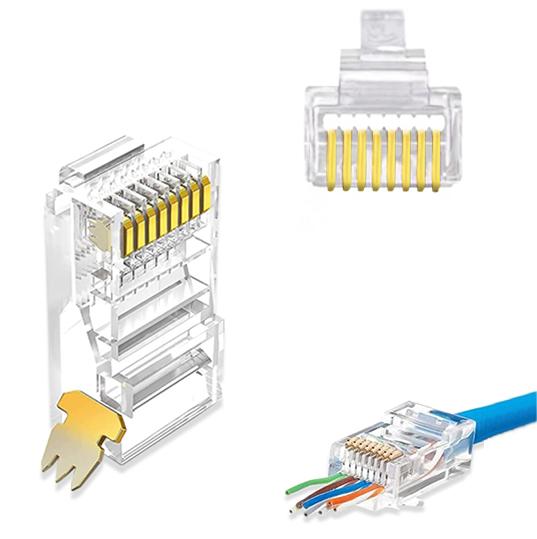

The camera end needs to be equipped with a fiber optic transceiver (to convert electrical signals into optical signals), and the patch cord itself cannot be directly connected to a regular camera.

The side of the video recorder (NVR) needs to be equipped with an optical port card or an external transceiver (to increase fault points).

Cost sensitive, use with caution:

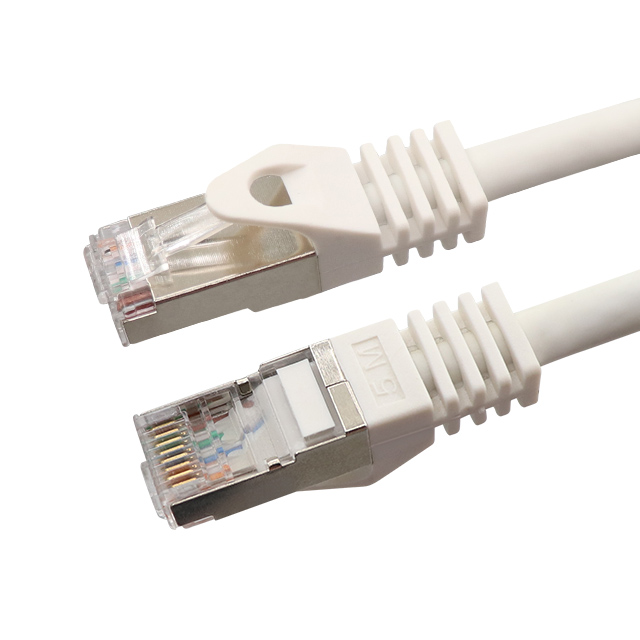

The cost of retrofitting a single monitoring point is increased by 3-5 times (transceiver+patch cord+fusion), and shielded twisted pair cables are preferred for short distance scenarios within 30 meters.

3. Operation and maintenance risk control

Physical protection defects:

Outdoor wiring requires armored patch cords (anti rodent), while ordinary PVC sheathed patch cords are prone to breakage due to compression in pipelines.

The wiring of the camera pole needs to be protected by a waterproof box, and the LC connector is prone to oxidation and failure when exposed to moisture.

Link diagnosis difficulty:

Ordinary network management software cannot monitor the status of patch cord cables. When interrupted, manual positioning with an optical power meter is required (compared to remote ping measurement with copper cables).

| Aspect | Feasibility & Best Practices | Critical Restrictions |

| Physical Connectivity | • Required: Media converters (fiber to copper) at camera/NVR ends • Direct connection: Only for fiber-enabled IP cameras/NVRs | • Never plug directly into standard BNC/RJ45 ports • Incompatible with analog CCTV without encoder |

| Optimal Use Cases | • Long-distance (>100m) camera links • High-EMI environments (e.g., substations) • 4K+/ultra-HD camera feeds | • Short-range indoor cameras (<30m) • Budget-constrained deployments |

| Cable Selection | • Outdoor runs: Armored jumpers (rodent/impact-proof) • Vertical risers: Bend-insensitive fiber (elevator cabs) • High-bandwidth: OM3/OM4 for ≤500m | • Avoid PVC-sheathed jumpers in conduits • Prohibit tight bends (<30mm radius) |

| Deployment Risks | • Water ingress: LC/SC connectors require IP67 junction boxes • Power instability: Media converters need dedicated UPS • Diagnostic gaps: No SNMP monitoring for fiber links | • Mixed cable trays with power lines (fire hazard) • Unlabeled strands causing cross-connect errors |

Operational Comparison vs. Copper Cabling

| Factor | Fiber Jumper Advantage | Copper Advantage |

| Signal Integrity | Immune to EMI/RFI (critical near machinery) | Vulnerable to motor interference |

| Bandwidth Capacity | Supports 4K/8K streams without degradation | Limited to ≤4K over Cat6 (>100m) |

| Total Cost | Lower lifetime cost for >24 camera mega-systems | 40% cheaper for small-scale installations |

| Maintenance | No corrosion; 10+ year lifespan outdoors | Regular termination rework required |

cooperate with PUXIN?

Contact us to find out how our products can transform your business and

take it to the next level.