Can you reuse ethernet keystone jacks?

2025-12-08

Keystone Jack Reuse Practical Guide

Content

I. Prerequisites for Reusability

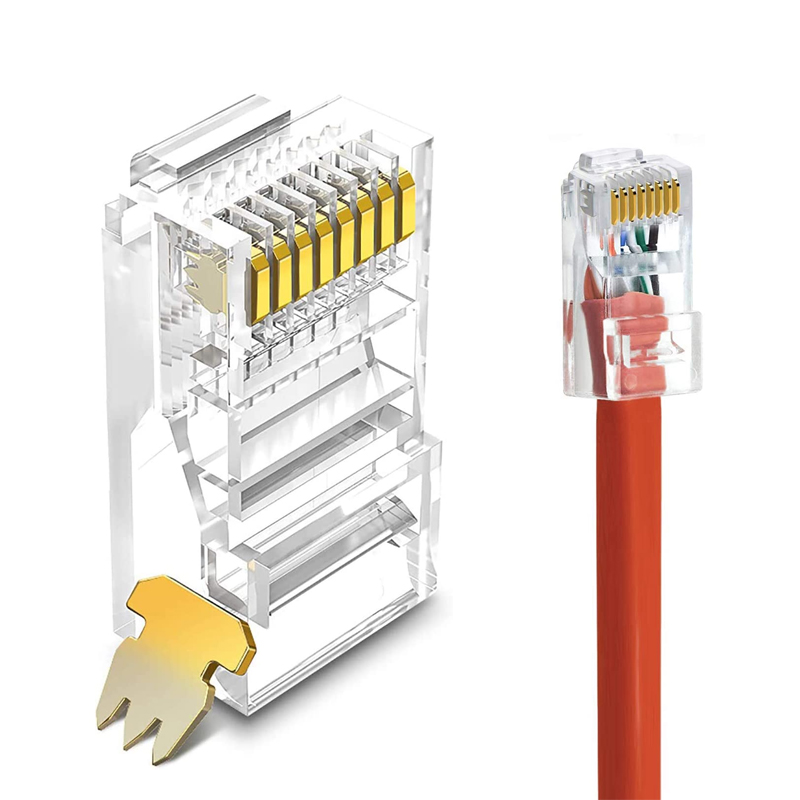

• Complete Physical Structure

Plastic clips are intact (elastic rebound when pressed)

IDC wire slot metal pieces are flat (no warping or deformation)

RJ45 contact plating is not worn (uniform gold color, no black spots)

• Compliant Historical Use

Only connected to standard PoE devices (≤30W)

Not exposed to water/oil corrosion

Wiring attempts ≤ 2 times (IDC blade lifespan limit)

II. Scenarios Where Reuse is Absolutely Prohibited

• Discard immediately in these cases:

Used with PoE++ power supply exceeding 60W (contacts yellowed and carbonized)

Used for outdoor surveillance (UV aging makes plastic brittle)

Plugged in and out more than 50 times (metal fatigue leading to poor contact)

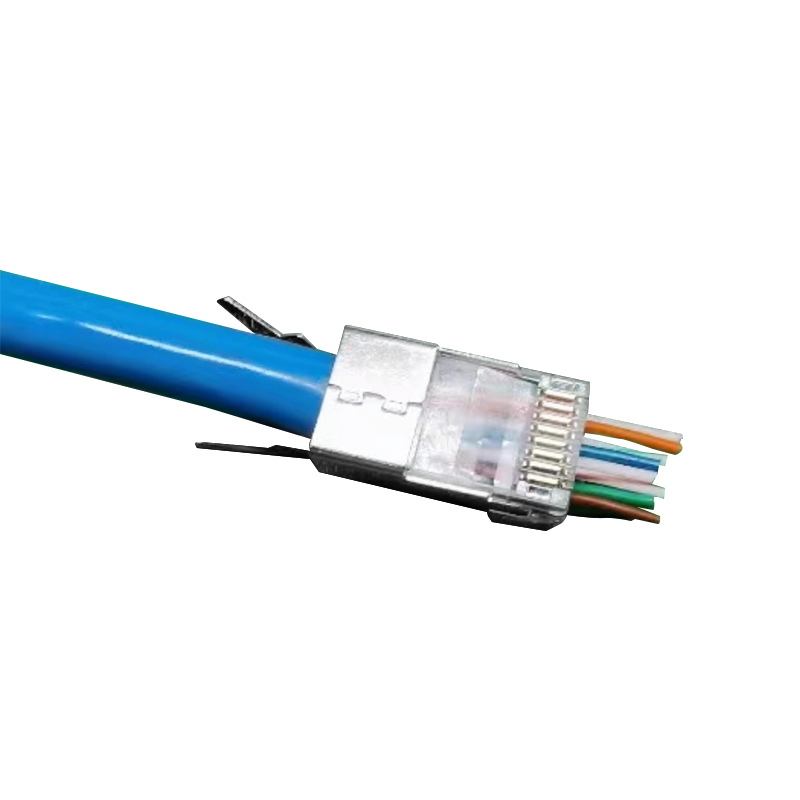

Shielding Jack grounding tab broken (compromising anti-interference)

III. Safe Disassembly Steps

• Removing from the panel:

Use a small screwdriver to push the bottom tab (stop when you hear a "click")

Do not use pliers to pull forcefully (will break the cable)

• Separating the old network cable:

Remove residual wire ends from the wiring slot with a needle

Avoid scratching the IDC metal pieces with the blade

IV. Refurbishment Operation Three Key Elements

| Step | Critical Actions | Emergency Tool Alternatives |

|---|---|---|

| Deep Cleaning | Gently wipe contacts with alcohol wipes | Use electronics spray + soft brush |

| Function Testing | Punch-down scrap cable → test continuity | Connect phone-to-RJ45 dongle |

| Protection Prep | Apply lube to plastic clips | Dab petroleum jelly (avoid contacts) |

V. Reuse Risk Control

• Marking Management:

Attach an orange label to the casing (indicating "Reused 1 time")

Mandatory disposal after more than 3 uses

• Scenario Restrictions:

Only used for non-critical equipment (such as conference room IP phones)

Not allowed for servers/security backbone networks

• Emergency Plan:

Reuse Jacks have a 30% higher failure rate

Keep spare new parts of the same model readily available for quick replacement

cooperate with PUXIN?

Contact us to find out how our products can transform your business and

take it to the next level.