How to test fiber optic patch cords?

2025-09-22

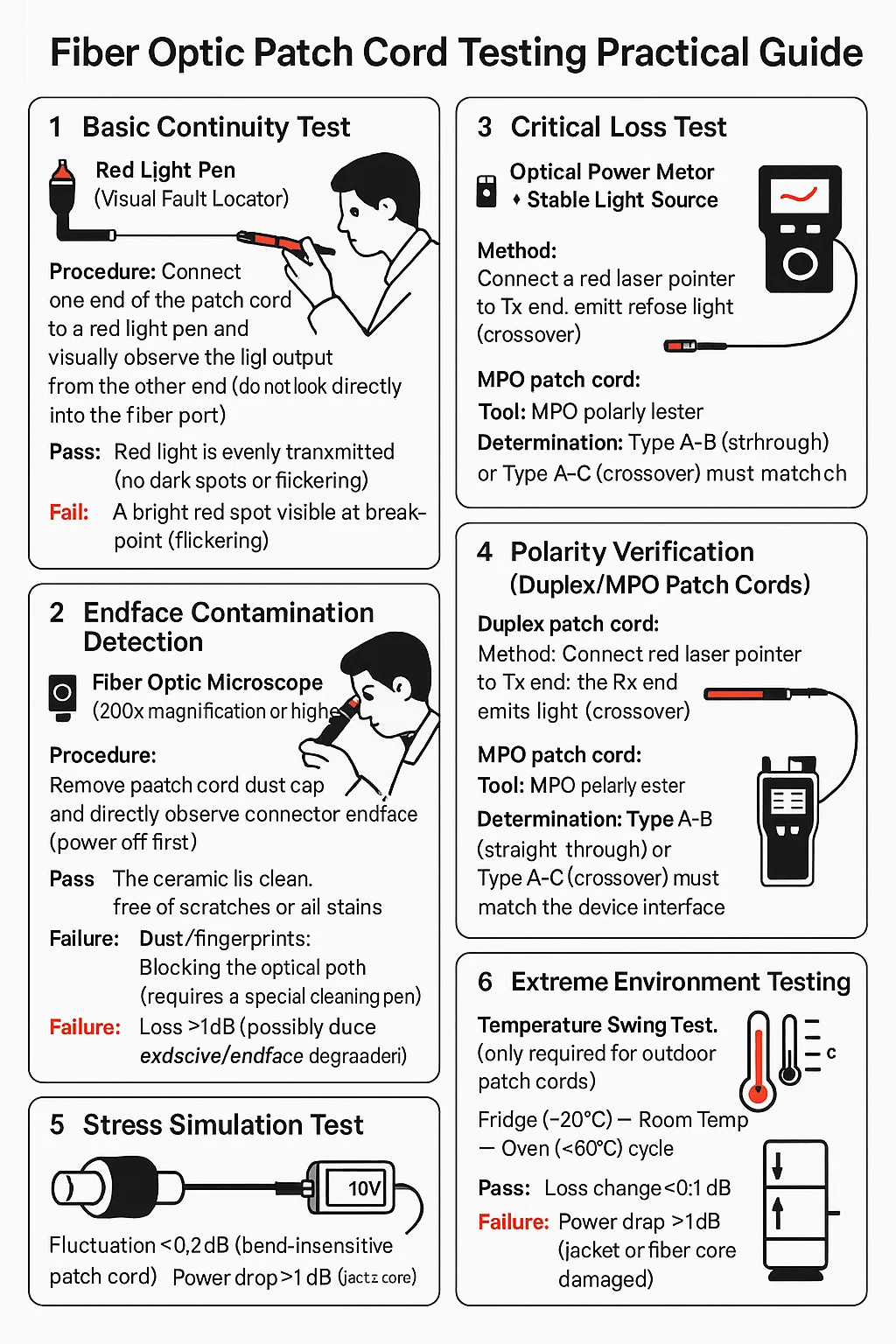

Fiber Optic Patch Cord Testing Practical Guide

1. Basic Continuity Test

Tool: Red Light Pen (Visual Fault Locator)

Procedure: Connect one end of the patch cord to a red light pen and visually observe the light output from the other end (do not look directly into the fiber port).

Pass: Red light is evenly transmitted (no dark spots or flickering).

Fail: A bright red spot is visible at the breakpoint (the location of the fiber core break).

2. Endface Contamination Detection

Tool: Fiber Optic Microscope (200x magnification or higher)

Procedure: Remove the patch cord dust cap and directly observe the connector endface (power off first).

Pass: The ceramic sleeve is clean, free of scratches or oil stains.

Failure:

Dust/fingerprints: Blocking the optical path (requires a special cleaning pen).

Cracks/chips: Immediately discard (irreparable).

3. Critical Loss Test

Tool: Optical Power Meter + Stable Light Source

Procedure: Connect the light source to one end of the patch cord and emit a reference light (e.g., 1310nm). Connect a power meter to the other end and read the loss value (dB).

Pass:

Multimode patch cord: ≤0.5dB (within 100 meters).

Single-mode patch cord: ≤0.3dB (within 1 kilometer).

Failure: Loss >1dB (possible: excessive bending/endface degradation).

4. Polarity Verification (Duplex/MPO Patch Cords)

Duplex patch cord:

Method: Connect a red laser pointer to the Tx end; the Rx end should emit light (crossover).

MPO patch cord:

Tool: MPO polarity tester

Determination: Type A-B (straight-through) or Type A-C (crossover) must match the device interface.

5. Stress Simulation Test

Scenario: Risk of bending/pulling the patch cord after deployment

Procedure:

Wrap the patch cord three times around a 4cm diameter cylinder.

Monitor the optical power fluctuation in real time during the test.

Pass: Fluctuation ≤0.2dB (bend-insensitive patch cord). Failure: Power drop > 1dB (jacket or fiber core damaged).

6. Extreme Environment Testing

Temperature Swing Test (only required for outdoor patch cords):

Fridge (-20°C) → Room Temperature → Oven (+60°C) cycle 3 times.

Pass: Loss change < 0.1dB.

Waterproof Test (IP67-rated patch cords):

Immerse the connector in water for 30 minutes, wipe dry, and measure insulation resistance (> 1000MΩ).

Prohibition Methods and Alternative Solutions

cooperate with PUXIN?

Contact us to find out how our products can transform your business and

take it to the next level.