How to fix fiber optic patch cord?

2025-09-29

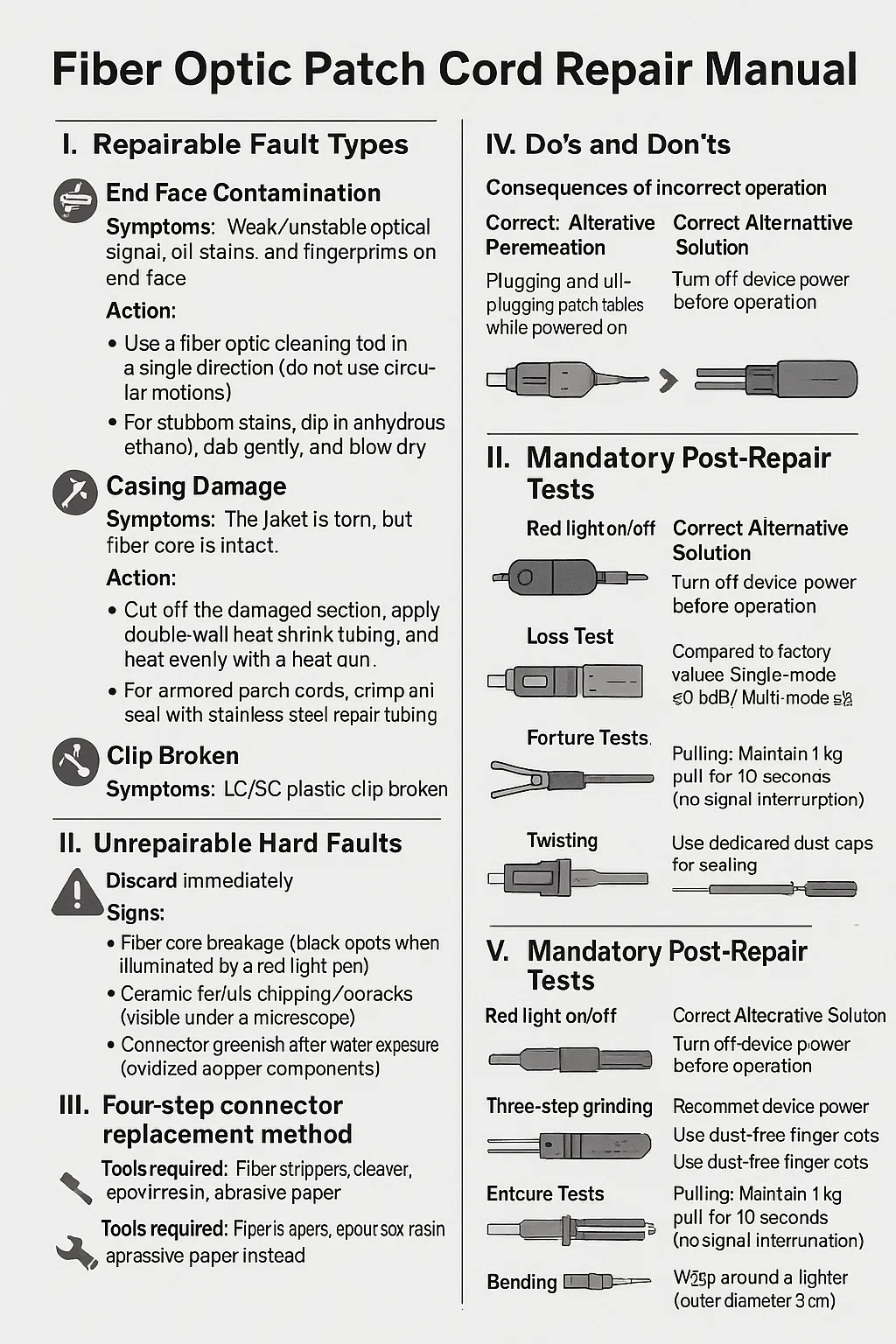

Fiber Optic Patch Cord Repair Manual

I. Repairable Fault Types

End Face Contamination

Symptoms: Weak/unstable optical signal, oil stains, and fingerprints on the end face

Action:

Use a fiber optic cleaning rod in a single direction (do not use circular motions).

For stubborn stains, dip in anhydrous ethanol, dab gently, and blow dry.

Contraindications: Do not use cotton swabs or paper towels (fiber residue is a concern).

Casing Damage

Symptoms: The jacket is torn, but the fiber core is intact.

Action:

Cut off the damaged section, apply double-wall heat shrink tubing, and heat evenly with a heat gun.

For armored patch cords, crimp and seal with stainless steel repair tubing.

Clip Broken

Symptoms: The LC/SC plastic clip is broken.

Action: Replace with a metal-shelled connector of the same model (re-termination is required).

II. Unrepairable Hard Faults

Discard immediately. Signs:

Fiber core breakage (black spots when illuminated by a red light pen)

Ceramic ferrule chipping/cracks (visible under a microscope)

Connector greenish after water exposure (oxidized copper components)

One fiber in an MPO patch cord is defective

III. Four-step connector replacement method

Tools required: Fiber strippers, cleaver, epoxy resin, abrasive paper

Fiber end removal: Cut off the damaged end, leaving at least 15cm of excess fiber. Strip off 3cm of outer jacket and clean the fiber core with an alcohol wipe. Thread a new connector. Insert the bare fiber into a new LC/SC ceramic sleeve. Inject blue epoxy resin and cure for 30 minutes. Precision cutting: Use a fiber cleaver to vertically remove the excess fiber core. The cross-section should protrude ≤0.5mm from the sleeve. End face polishing

Three-step grinding:

Coarse grinding (draw an "8" shape 10 times with 12μm sandpaper)

Fine grinding (draw an "8" shape 20 times with 3μm sandpaper)

Microscopic examination (no scratches under a 200x microscope)

IV. Do's and Don'ts

| Wrong Operation | Consequence | Correct Alternative | Critical Level |

|---|---|---|---|

| Hot-plugging without verification | Burns optical module circuits | Power off equipment & verify shutdown | (Fatal) |

| Touching ferrules with bare fingers | Skin oils corrode anti-reflective coating | Wear lint-free gloves or use vacuum tweezers | (Severe) |

| Using adhesive tape on connectors | Adhesive seeps into optical path blocking light | Install OEM dust caps immediately | (High) |

| Stripping fiber with scissors | Glass shards embed in skin/eyes | Use precision fiber strippers (e.g., Miller) | (Severe) |

V. Mandatory Post-Repair Tests

Red light on/off. Acceptable if no dark spots are present throughout the entire section (especially at bends).

Loss Test

Compared to factory values: Single-mode ≤0.5dB / Multi-mode ≤0.8dB.

Torture Tests

Pulling: Maintain a 1kg pull for 10 seconds (no signal interruption).

Twisting: Twist both ends 180° (loss fluctuation <0.3dB).

Bending: Wrap around a lighter (outer diameter 3cm) three times.

cooperate with PUXIN?

Contact us to find out how our products can transform your business and

take it to the next level.