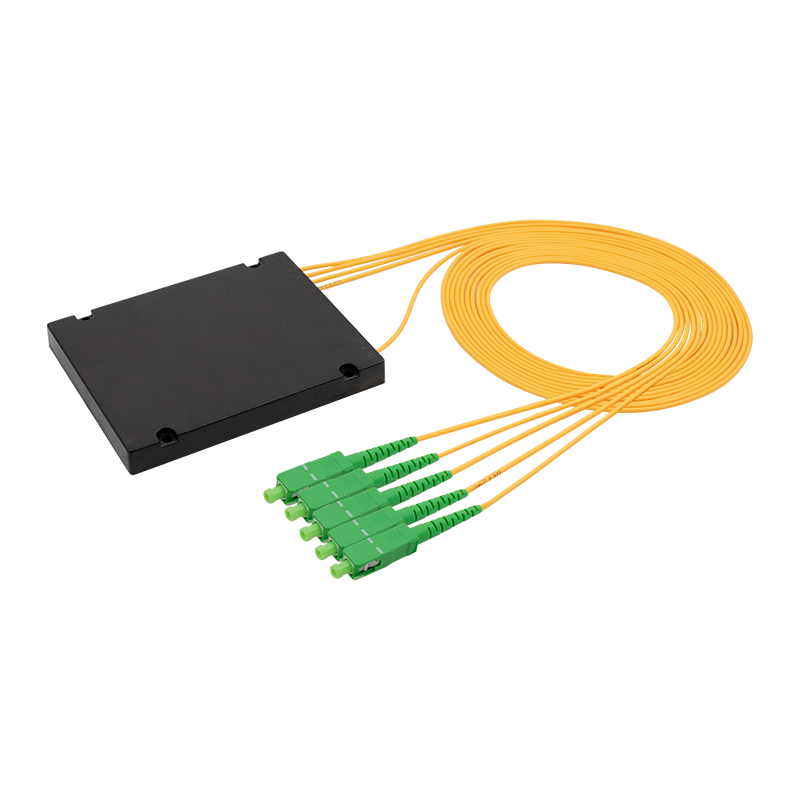

OEM/ODM Fiber Optic Splitter

Fiber Optic Splitter Supplier

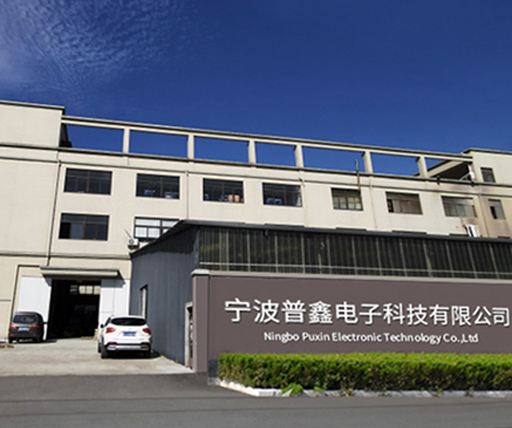

PUXIN Story

Ningbo Puxin Electronic Technology Co., Ltd has established for more than 15 years, which is specialized in the production of integrated network cabling products and optic fiber products, including copper CAT5E, CAT6, CAT6A, CAT7, CAT8, such as keystone jack, patch panel, RJ45 connector, patch cord, and other related products.

As a China Fiber Optic Splitter Supplier and OEM/ODM Fiber Optic Splitter Company , Our company has advanced manufacturing equipment, testing equipment, and scientific and quality control methods. We have rich experience in manufacturing OEM and ODM products. At present, our products have been exported to Southeast Asia, South America, Australia, the Middle East, Europe, and other countries.

We sincerely look forward to working together with domestic and foreign merchants to create common development. Friends from all walks of life are welcome to visit, guide, and negotiate business.

Complete And Stable Supply Chain

Our R&D team has more than 10 years of experience in the production and design industry. We can accept OEM and ODM orders, you only need to provide customized sizes and shapes to enjoy professional customization services.

Create Safer Cabling Connections

PUXIN has an on-site engineering team and a mold manufacturing team equipped with complete production lines including stamping, plating, injection molding, automatic insertion and assembly capabilities to ensure that your products meet the requirements of safety standards for all processes.

The Entire Supply Chain is Third-Party Certified

We insist on using new environmentally friendly raw materials. The finished products must pass ROHS and FLUKE testing before they can be sold. Related products have been certified by well-known institutions in the industry such as CCC, CE and ROHS. certificate and holds multiple product research and development patents.

PUXIN Collaboration System

Our goal is to provide the market and customers with customized solutions, whether it is a single product or a complete set of products.

We will respond patiently and carefully to any inquiries and feedback from customers, and provide professional and reasonable quotations.

For any new products from customers, we will communicate with customers very professionally, listen to their opinions and give useful suggestions to ensure high-quality products.

For any orders from customers, we will complete them on time, quality and quantity.

We take the time and effort to solve every problem, no matter how mundane you may encounter it. We will always accommodate you, and you'll find that we speak your language and understand your technical issues. This is why we have been so successful over the years working with our clients from more than 30 countries.

Latest Updates

Provide you with the latest enterprise and industry news.

Fiber Optic Splitter Industry Knowledge

How does humidity affect the connection point stability of fiber optic splitter?

Humidity has a direct impact on the stability of the connection points of fiber optic splitters, which is mainly reflected in the following aspects:

Corrosion: The presence of water vapor and other chemicals in high-humidity environments can cause corrosion of metal components at connection points. Especially for metal joints or connectors at connection points, long-term exposure to moisture will accelerate the oxidation and corrosion of the metal, causing the connection to lose electrical contact, thereby reducing the stability and reliability of signal transmission.

Media Moisture Absorption: The media surrounding the splitter connection point (such as connectors, adapters, etc.) may absorb moisture, causing the performance of the media to change. For example, moisture absorption of the media in a fiber optic connector may cause moisture to accumulate inside the connector, affecting the connector's optical properties and connection quality.

Optical performance changes: Humidity changes may cause changes in the refractive index at the fiber connection point, thereby affecting the transmission performance of the optical signal at the connection point. Especially in high-humidity environments, water films or water droplets may form around the fiber connection points, changing the transmission path and refractive index of the optical signal, resulting in increased signal attenuation or scattering.

Reduced connector sealing performance: High humidity environments may cause the aging and damage of connector seals (such as rubber rings, sealants, etc.), causing the connector to lose good sealing performance. Connectors that have lost their sealing properties are susceptible to the intrusion of moisture and contaminants, resulting in reduced optical performance and connection quality at the connection point.

Therefore, in order to ensure the stability of the fiber optic splitter connection point, when used in a humid environment, it is necessary to select connectors and adapters with good moisture-proof performance, and to regularly check and maintain the connection point to reduce the negative impact of humidity on the connection stability. Influence.

Why does fiber optic splitter need to be anti-static when repairing it?

The reason why anti-static is required during fiber optic splitter maintenance is mainly because static electricity may cause damage to the electronic components inside the fiber optic splitter. Electrostatic discharge is a sudden and intense release of electrical current that can damage the tiny structure of electronic components, causing them to degrade or fail completely. During the maintenance process of optical fiber splitters, electrostatic discharge may come from many aspects, such as static electricity carried by the maintenance personnel's bodies, static electricity accumulation in the working environment, etc.

In order to prevent static electricity from causing damage to fiber optic splitters, maintenance personnel need to take a series of anti-static measures during the maintenance process. For example, wear anti-static work clothes, wear anti-static gloves and bracelets, use anti-static tools and equipment, and keep the work environment clean and dry. These measures can effectively reduce the generation and accumulation of static electricity and protect the electronic components inside the fiber optic splitter from static electricity damage.

In addition, anti-static protection during fiber optic splitter maintenance is also an important part of ensuring the smooth progress of the maintenance work. Static interference may cause unexpected situations during the maintenance process, such as equipment failure, data transmission errors, etc., thus affecting maintenance efficiency and accuracy. Therefore, when repairing fiber optic splitters, you must pay attention to anti-static work to ensure the safety and smooth progress of the repair process.

cooperate with PUXIN?

Contact us to find out how our products can transform your business and

take it to the next level.

Ningbo Puxin Electronic Technology Co., Ltd. is a professional supplier of electrical engineering and integrated wiring product research and development and manufacturing.

-

No.43 of Xiaotuanpu Road, Guanhaiwei Town, Cixi Ningbo City, Zhejiang, China

-

-

8615924366333

-